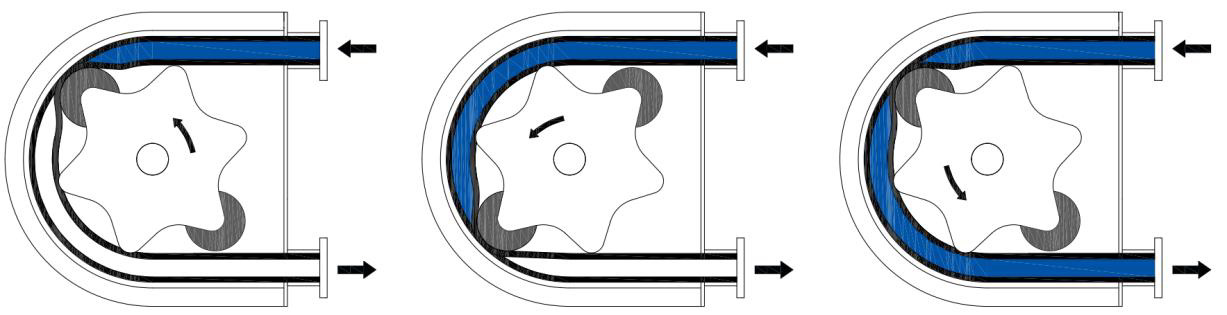

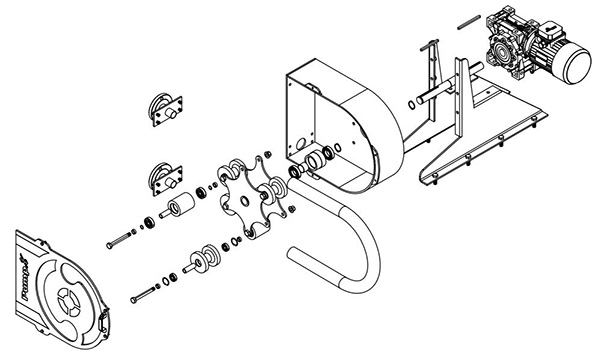

PumpX adopts the roller principle in it’s peristaltic pump RollX which pumps by the compression of an arched loop of rubber hose with two diametrically opposed rollers With this rotational motion fluid is pushed ahead inside a hose which is compressed and relaxed by the rollers mounted on a rotor.

When each roller reaches the end of the loop, the reinforced hose immediately returns to its original shape creating a strong vacuum pulling more fluid inside thus enabling suction This enables the pump in handling of the toughest pumping challenges, including extremely abrasive and aggressive fluids, solid loaded liquids, as well as shear sensitive and very viscous materials in a wide variety of industries.

BuildPress Inc traces its roots back to 1989 in Colorado and since then have never looked back. With thousands of successful projects under our belt, we can proudly say that we are one of the most trusted construction companies in Colorado performing both domestic and international construction work.

For more than 25 years, Construction has offered a wide range of construction services in Colorado, many other cities of United States and around the world. We strive to maintain the highest standards while exceeding client’s expectations at all levels. We not only honor commitments, but are known for meeting tough deadlines while delivering nothing but the best. We aim to create a responsive client relationship that allows us to meet and even exceed the goals of each of our projects.

Two stainless steel rollers mounted at 180 on a rotor compress alternatively and consequently a specially designed hose in a concentric guide pushing the pumped liquid from the suction to the discharge side Roller movement compresses the hose along the casing wall creating a constant vacuum at the suction side of the pump In this way, liquids are displaced within the hose and do not get in contact with any metal part

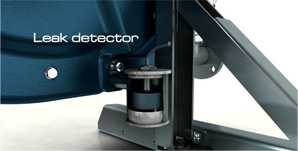

No mechanical seal that can cause leakage.

RollX pumps displace the medium in a hose, requiring only one component to be changed, which means that maintenance costs are considerably lower than other pump types.

Reversible flow, suction and discharge

Due to the peristaltic effect.

PumpX RollX pumps can self prime with a suction lift reaching 9.8 meters

Wear resistant hose is the only part that is in contact with the medium.

The RollX range is designed and manufactured for heavy duty industrial use.

Below < 70 dB at 1 meter.

PumpX pumps have the ability to run dry continuously

RollX pumps are the result of extensive research and development adopting the rollers mechanism but with a new energy and cost efficient design.

RollX pumps are the result of extensive research and development adopting the rollers mechanism but with a new energy and cost efficient design.

RollX pumps can run at higher rpms and still produce a longer hose lifetime.

Due to the almost frictionless operation and design RollX doesn’t generate heat which increases the overall pump and hose life.

RollX pumps need lower power to transfer the same quantity of fluid compared to other pump types so it is extremely economic in operation.

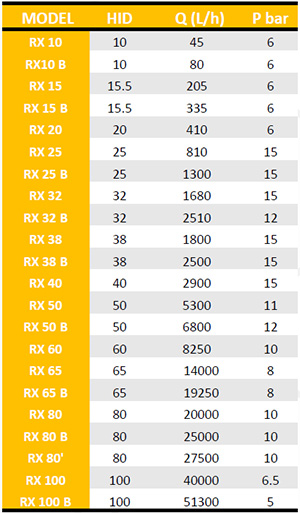

RollX pumps are available in many sizes and capacities covering a wide range flow rates and applications for many industries.

RollX pumps are oil free.

RollX hoses have proven an excellent performance with the carefully designed stainless steel rollers.

Special RollX large sizes available such as RX125 & RX150 with flow rates reaching 150m 3 hr Any of the RollX models can be modified to suit a specific application

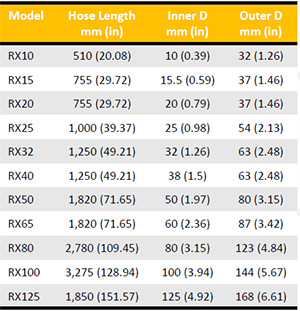

The hose of a the RollX pump is the only component that comes in contact with the pumped medium. Our hoses are manufactured from high quality compounded rubber, reinforced by layers of nylon. The hose designed with precision for efficiency, accuracy, longevity, and optimal compression.

The hose of a the RollX pump is the only component that comes in contact with the pumped medium. Our hoses are manufactured from high quality compounded rubber, reinforced by layers of nylon. The hose designed with precision for efficiency, accuracy, longevity, and optimal compression.

PumpX hoses are available in different materials of construction, all of which have been chosen for their high levels of fatigue resistance:

Capacity: up to 150 m 3 /h

Viscosity: up to 100000 cps

Temperature of pumped medium: up to 110 o C

Discharge pressure: up to 15 bar

Self priming: up to 9.8 m

The following accessories could be supplied upon request: